In the previous post, we looked at the several feaures that looked important to the basics of the design. We wanted to hold the part in the angles that were needed for soldering. We wanted the hold to secure for the connector itself. What was missing was considering the manufacturability. A consideration of any design, is can it be produced economically for an acceptable market price. So we challenged ourselves to come up with a simple design.

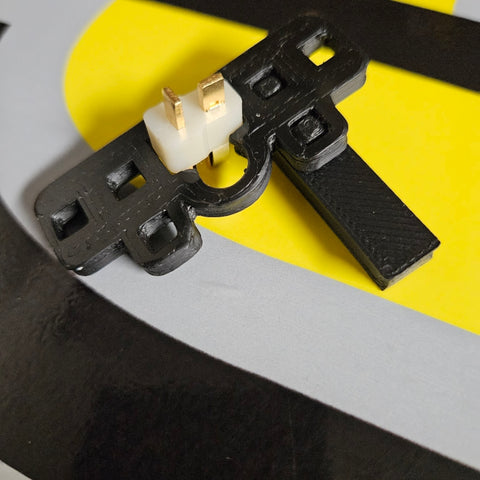

We thought instead of worrying about a stand, if someone had a vice they could hold onto a leg. A spring effect was integrated so the connector could be held. Overall, the design made for two simple parts. The trickiest part was getting the spring effect to work where it would not be too hard to put the part in nor would it slip out to easily while soldering.

Looking at the design, we knew this would be perfect for manufacturing in an injection molding process. That said, it felt too simple. In the next, iteration we will look to see for a more substantial piece.